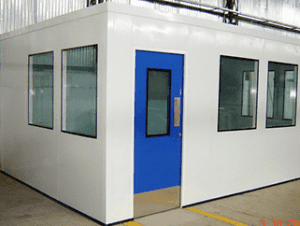

Prefabricated Clean Rooms

Clean rooms are basically designed to preserve highly low level of particles such as dust, airborne organisms and vaporized particles; a clean environment designed to reduce contamination of processes and materials. Clean rooms are meant for airflow. KrupaShree a leading clean rooms supplier in India, stays up to date with the latest regulation. We know what your clean room project needs to be certified. Initially we identify the process of your facility and quantity of production. Secondly, we identify the location of clean room, ascertain plumbing, electrical and HVAC tie needed to complete the project. They required lot of air and a controlled temperature and humidity. Basically Clean rooms have high level of cleanliness.

Prefabricated Clean Room Manufacturer & Supplier in India

KrupaShree a high quality prefabricated clean room manufacturer and supplier in India, makes the right noise for making quality products using materials that are affordable and yet match up to the strict quality parameters. Before installing modular cleanroom structures, you should gather every speck of knowledge you can gather for making informed purchases.

For Cleanroom Design & Build Approach & Consultations

What Are Clean Rooms?

According to ISO standards, a clean room (or cleanrooms) is a controlled environment (temperature, airflow, humidity) where the cleanest area is achieved through the filtering of dirt particles, airborne microbes, aerosol particles, etc. Prefabricated modular cleanrooms are designed, constructed, and operated in such a manner that the cleanliness is not compromised in any way. Modular Clean rooms are classified depending upon the contamination level of the number of particles allowed per cubic meter. For further queries related to cleanrooms, contact us.

Where are Modular Cleanrooms Used?

As a cleanroom manufacturer in India, our cleanroom products are used in various areas including, but not limited to;

- Manufacturing companies

- Research and academic facilities

- Pharmaceutical companies

- Medical laboratories

- Aerospace industries

- Military application

- Ophthalmology lens and other products manufacturing

- Nanotechnology

- Electronic parts manufacturing

Advantages Of Cleanrooms

- Modular cleanrooms are easily constructed in a shorter period of time as the larger part of the construction (sturdy frame, prefabricated panels) is done off-site.

- As they require less energy to maintain humidity and temperature, cleanrooms require less cost for maintenance.

- Modular cleanrooms are eco-friendly as they are made of recycled materials.

- They are easier to maintain as any faulty part can be changed easily with a walkable ceiling which you can access from above while avoiding humidity.

- They provide effective performance in environment control as they are fitted with HEPA filters.

prefabricated Cleanroom Classifications

- Softwall cleanrooms: Made of fabric walls, easily assembled and disassembled, they are perfect for rigorous application.

- Hardwall cleanroom: Made with a sturdy frame and panels of steel, PVC, acrylic, tempered glass, they are more permanent than softwall versions.

- Modular cleanroom: Made with pre-cut components, they can be disassembled or assembled according to requirement on-site; known for their versatility, low-cost materials.

- Clean lab: They may be stationary or mobile, mostly used for pharmaceutical manufacturing and research.

- Positive air pressure room: To keep contaminated air out of the room, filtered air is pumped into the room. They are used where hazardous substances are not used.

- Negative air pressure room: In these rooms, filtered air replaces contaminated air. They are used for applications where hazardous chemicals are involved.

prefabricated Cleanroom Wall Systems

- Smooth FRP: They are extremely lightweight, durable, and do not let dust particles settle on them making them ideal for application.

- HP Panels: Built with tongue and groove panel connections, they are class-1 high-performance panels that are lost-lasting.

prefabricated Cleanroom Grade A, B, C, D

- Grade A: This is suitable for high-risk operations like filling zones, stopper bowls, open ampoules, and vials. These are provided by a laminar airflow workstation.

- Grade B: Provides background environment for grade A zone items that need aseptic preparation and filling.

- Grade C & D: These are used in less critical tasks during less-critical manufacturing processes.

Prefabricated Clean Rooms Supplier in India

Being the leading cleanroom supplier and manufacturer in India, we design cleanrooms according to clients’ requirements. They are constructed with PUF/ EPS panels. We provide service from up to inception, interface with HVAC, electrical to the design stage. We provide prefabricated cleanrooms for various industries such as pharmaceuticals, food, medical devices, electronics, automobiles, etc.

We also provide premium quality prefabricated cleanroom panels and clean rooms at cost-effective prices. Following ISO and CGMP standards, we stock large quantities of cleanroom materials for bulk orders. We make the highest quality cleanroom components such as clean room doors, ceiling tiles, terminal fillers, cleanroom filters, lights, curtains, strip doors, etc. To give a quality performance, we test the products numerous times to meet customers’ highest standards.

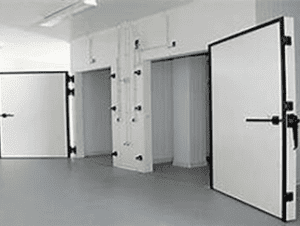

Cold Storage Rooms And Cold Storage Chambers In PAN India

We manufacture and provide modular and prefabricated cold storage rooms and cold storage chambers for the food and pharmaceutical industries. Apart from these industries, these rooms are used in the seafood, floriculture, and cream industry. Our cold storage rooms are highly in demand in the market.

Our cold storage rooms solution consists of pre-coolers, food ripening chambers, blast freezers, large-scale walk-in cold rooms, pre-engineered cleanrooms for food storage. They are manufactured with premium sandwich panels (PUF/EPF, glass wool, Rockwool) for wall and roofing, doors with hinges, locks, handles, and release buttons- all of these are made while keeping in mind international standard joinery systems.