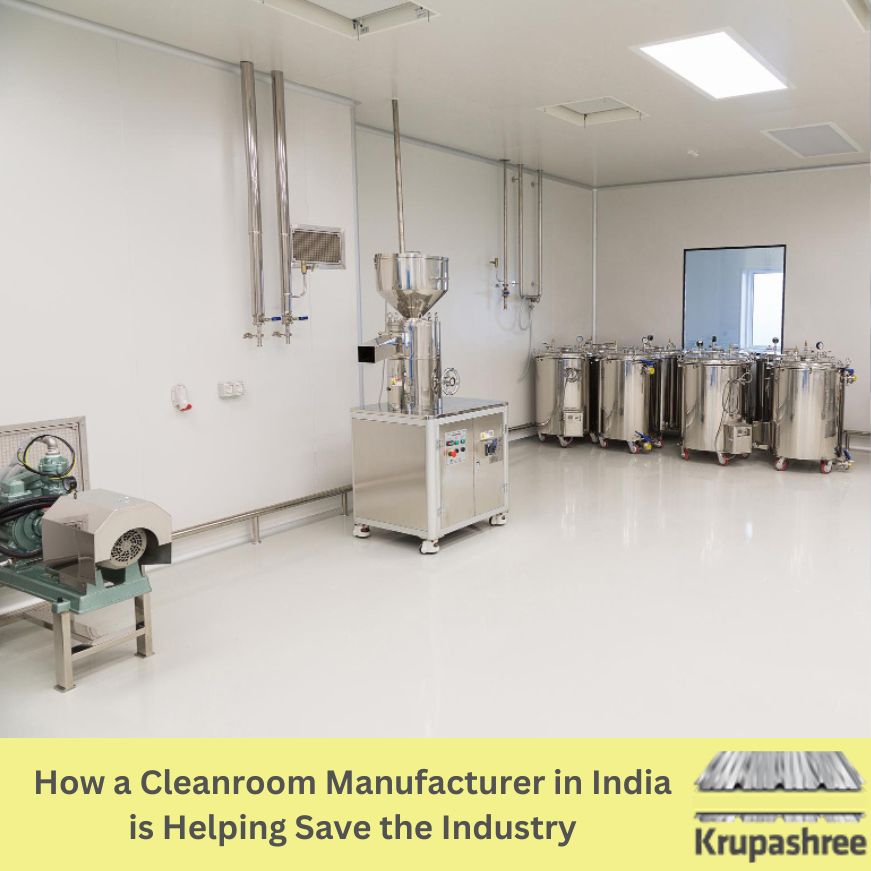

A cleanroom is a controlled environment that reduces contamination and removes airborne particles. Several industries require cleanrooms because tiny particles can impair the production process and assembly quality. You can easily find cleanrooms in today’s pharmaceutical, semiconductor, biotechnology, medical device, biosciences, optical, aerospace, automobile, and military facilities, among other industries. A cleanroom manufacturer in India can provide the best options for all these industries.

High employment in cleanrooms has been generated in other sectors. Practitioners carry out some astonishing applications and experiments. Cleanrooms and regulated surroundings are an integral part of the healthcare and pharmaceutical sectors. The clean environment of the cleanroom complies with precise specifications and stringent industrial compliances.

Krupashree PEB is a leading cleanroom manufacturer and supplier in India. Contact us to get the best solutions.

How Cleanroom Helps Different Industries

Cleanrooms are helpful in multiple industries. They are a sustainable and high-quality option to protect the environment and surroundings where people are operating. Here are a couple of ways a cleanroom supplier and manufacturer in India suggest a cleanroom can help in:

1. Reducing air waste by air recycling

Since purifying air for a cleanroom is extremely expensive and the air within a cleanroom is not free, cleanrooms now utilize “green air” through the use of fan filtration units. These filters enable cleanrooms to maintain a consistent temperature, humidity level, and cleaner air by reusing air that was previously discarded as waste. Air waste reduction is economical and significantly lessens any environmental effects.

2. Reduction in material waste

Cleanrooms have upped its sustainability game and raised the bar for recycling cleanroom textiles through creative single-use clothing recycling initiatives. Several single-use cleanroom materials are recycled. This includes clothes, hairnets, lab gloves, and boot covers to name a few.

They are transformed into consumer-friendly green items like plastic benches, plastic seats and bulk plastic products. Other items are manufactured from repurposed single-use cleanroom clothes. With the aim of having zero waste by the year 2015, more than 99% of production waste has been diverted from garbage dumps through these new recycling activities.

3. Energy Efficiency

Cleanrooms are highly resource- and energy-dependent controlled environments. Achieving the goal of making cleanrooms more energy-efficient is made possible by modular cleanrooms. Modular cleanroom construction aims to use less materials and produce less waste during construction. The construction of new, more compact modular systems with less material usage has received the majority of attention. It also lowers the cleanrooms’ overall energy footprint.

The environment benefits more from small-scale construction, and if additional space is required in the future, the amenities can always be upgraded. An overcrowded cleanroom facility uses a lot of resources and energy.

The Cleanroom Landscape in India

Presently, the cleanroom market in India is worth over 5000 crores rupees. It will expand by another 1000 to 1500 crores in another 1-2 years. The national government has taken positive measures to increase the industrial sector’s confidence. This will lead to a boom in the cleanroom manufacturing industry in India.

Make in India Initiative

The Make in India initiative has given the sector, which was figuratively in a rut, a boost. According to several experts, this fresh push and encouraging policy actions would not only spur the incumbent companies to act but also encourage the innovators and new entrepreneurs to move into new fields to catch up with the future trends. This has led to a rise in the number of cleanroom manufacturers in India.

The overall healthy expansion of the business and rising need for biologic medications, many of which are delivered as sterile parenteral formulations, are key drivers of cleanroom technology demand in the pharmaceutical industry. The rising strength of many new small-molecule and biological medications, which necessitates unique containment systems and operational requirements, as well as increased operator safety standards are other factors.

As per Persistence Market Research, manufacturers of cleanroom technology face many difficulties. This includes rising demand for customized products, the high cost of building, installing, and maintaining cleanrooms, and the scarcity of operators with the requisite qualifications.

Also, some manufacturers are setting up cleanrooms to gain a competitive edge and draw in more customers. Moreover, strict controls can improve yields and operator productivity. Flexible containment options are appealing for development work. Cleanroom environments help avoid cross-contamination. It is essential when the toxicity of experimental products is frequently not well understood.

As a reliable cleanroom manufacturer and supplier in India, Krupashree PEB delivers top-quality cleanroom solutions at competitive pricing. Contact us today.

Conclusion

For many sectors as well as today’s and tomorrow’s new products, the cleanroom is essential. These are only a few uses for cleanroom settings. The scope is immense. The cleanroom industry in India is growing rapidly, and a cleanroom supplier and manufacturer in India like Krupashree PEB is experimenting with technologies to build the most sustainable and useful cleanrooms that can help all industries.